information to be updated

Prześlij opinię

Nieorganiczne spoiwo odporne na wysokie temperatury Dostawcy

Nieorganiczny klej wysokotemperaturowy

Nieorganiczne kleje wysokotemperaturowe, powstałe z nanomateriałów nieorganicznych w wyniku reakcji polikondensacji, to specjalistyczne kleje o niezwykłych właściwościach, takich jak:

- Niski współczynnik rozszerzalności: minimalizuje rozszerzalność cieplną.

- Wysoka wytrzymałość: zachowuje silne właściwości klejące.

- Odporność na wysoką temperaturę: wytrzymuje temperatury do 1100°C lub wyższe.

- Wodoodporność: Zapewnia silną ochronę przed wilgocią.

Kleje te zapewniają stabilną siłę wiązania i odporność na korozję nawet w wysokich temperaturach. Stosowane są przede wszystkim do klejenia powierzchni materiałów wysokotemperaturowych, takich jak szkło, ceramika i twarde stopy, tworząc jednolitą i gęstą warstwę ochronną, która skutecznie chroni podłoża przed uszkodzeniami cieplnymi.

Co więcej, ten produkt jest nietoksyczny, nieszkodliwy i niepalny, co czyni go idealnym ekologicznym materiałem wiążącym.

-

Wprowadzenie Produkcja krzemian potasu rozwiązania odgrywają kluczową rolę w różnych gałęziach przemysłu, takich jak rolnictwo, budownictwo i inżynieria chemiczna. Roztwory te, wytwarzane ...

CZYTAJ WIĘCEJ -

Wprowadzenie W ostatnich latach zapotrzebowanie na wysokowydajne produkty hydrofobowe gwałtownie wzrosło ze względu na rosnący nacisk na trwałość i ochronę w różnych gałęziach przemysłu. Jednym z najważ...

CZYTAJ WIĘCEJ -

Wprowadzenie Proszek krzemianu sodu , powszechnie określane jako szkło wodne lub płynne szkło w postaci płynnej, jest bardzo wszechstronnym związkiem o szerokim zakresie zastosowań w wielu ...

CZYTAJ WIĘCEJ

Why Are High-Temperature Resistant Inorganic Binders Crucial for Modern Industries?

In the rapidly advancing world of materials science, high-temperature resistant inorganic binders are playing an increasingly pivotal role in various industrial applications. These binders are essential components in many high-performance products that require both durability and heat resistance. Industries ranging from metallurgy to electronics, construction, and even energy rely on these unique materials for their efficiency, safety, and long-lasting performance.

The Science Behind High-Temperature Inorganic Binders

At their core, high-temperature resistant inorganic binders are designed to withstand extreme conditions without degrading. Unlike organic binders, which can burn or decompose at high temperatures, inorganic binders are made from materials that maintain their integrity under heat stress. These binders are typically composed of silicates, aluminosilicates, and other inorganic compounds, providing superior heat resistance, stability, and minimal expansion or contraction in response to temperature changes.

One of the most commonly used types of inorganic binders is sodium silicate, also known as water glass. Sodium silicate solutions are used as a binder in foundries, where molten metals are cast, and in the production of ceramics. These binders play a critical role in holding materials together while maintaining high thermal stability. Other compounds such as potassium silicate and lithium silicate are also utilized in specific applications, depending on the desired properties of the finished product.

The chemical structure of these materials makes them highly resistant to high temperatures, often withstanding temperatures in excess of 1000°C. This makes them indispensable in environments where the product will be exposed to intense heat, like furnaces, reactors, or engine components.

Why Is This Technology Important in Industry?

The growing demand for energy-efficient and sustainable technologies has led industries to seek materials that not only offer high performance but also contribute to environmental benefits. High-temperature resistant inorganic binders are at the forefront of these innovations, offering solutions for industries that require heat resistance while minimizing environmental impact.

In sectors like metallurgy, foundry, and ceramics, these binders are used extensively in producing refractory materials, which are crucial for processes like metal casting and smelting. Refractories, which line the interior of high-temperature furnaces, must endure the intense heat without deteriorating. Inorganic binders help create stable, durable products that are vital for maintaining the safety and efficiency of these systems.

As the demand for electronics and renewable energy technologies rises, the need for heat-resistant materials in the production of batteries, semiconductors, and heat exchangers has escalated. Here, high-temperature inorganic binders also play a crucial role in maintaining the integrity and longevity of electronic components that operate in high-temperature environments.

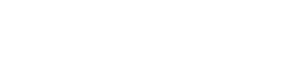

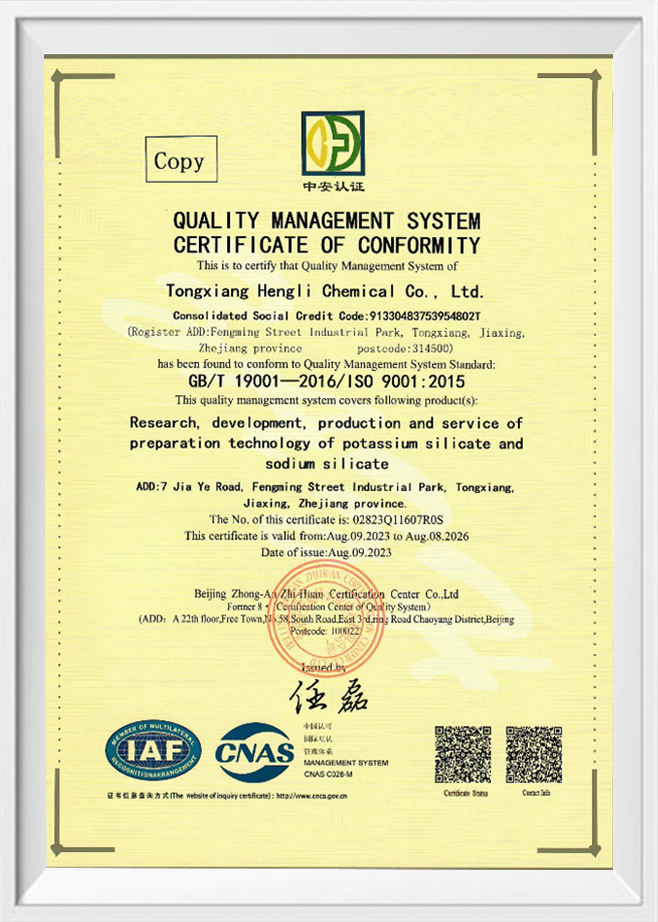

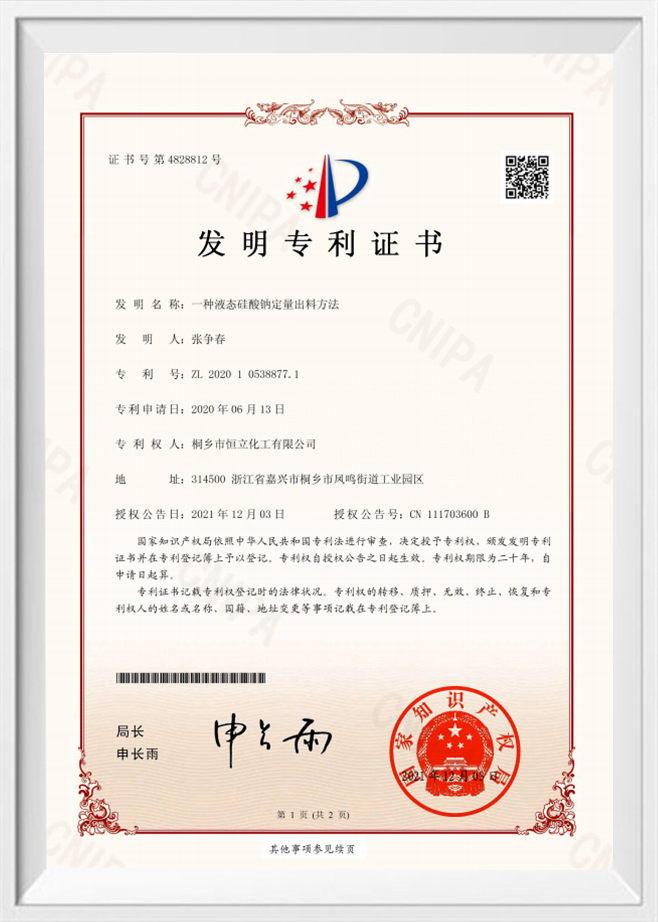

A key player in the field of inorganic binders is Tongxiang Hengli Chemical Co., Ltd., a company that has been leading the way in the production of high-quality inorganic binders since its establishment in 1997. Specializing in a wide range of inorganic silicon products, Hengli Chemical's offerings include sodium silicate, potassium silicate, silica sol, lithium silicate, and other high-temperature resistant adhesives.

Tongxiang Hengli Chemical Co., Ltd. stands out for its commitment to providing not only high-performance materials but also customized solutions that meet the specific needs of its customers. By producing more than 30 different types of products, the company serves diverse industries, from metalworking and construction to energy and electronics. Their high-temperature resistant adhesives, in particular, are highly regarded for their exceptional thermal stability, ensuring that they meet the stringent demands of industries that work with extreme heat.

High-temperature resistant inorganic binders are indispensable materials in modern industry. From metallurgy to electronics, these binders offer unparalleled durability and heat resistance that allow products to function effectively in extreme environments.As we look ahead, the ongoing development of these materials promises even more exciting possibilities, allowing industries to push the boundaries of what is possible.